Engine trouble can stop you in your tracks—literally and financially. Few things are more stressful than hearing that your vehicle needs major repairs. If your car’s engine is failing, you’re probably weighing whether fixing it is worth the cost. Rebuilding an engine can be innovative, but it doesn’t come cheap. Understanding what influences the price can help you plan better and avoid unwanted surprises.

What Does it Mean to Rebuild an Engine?

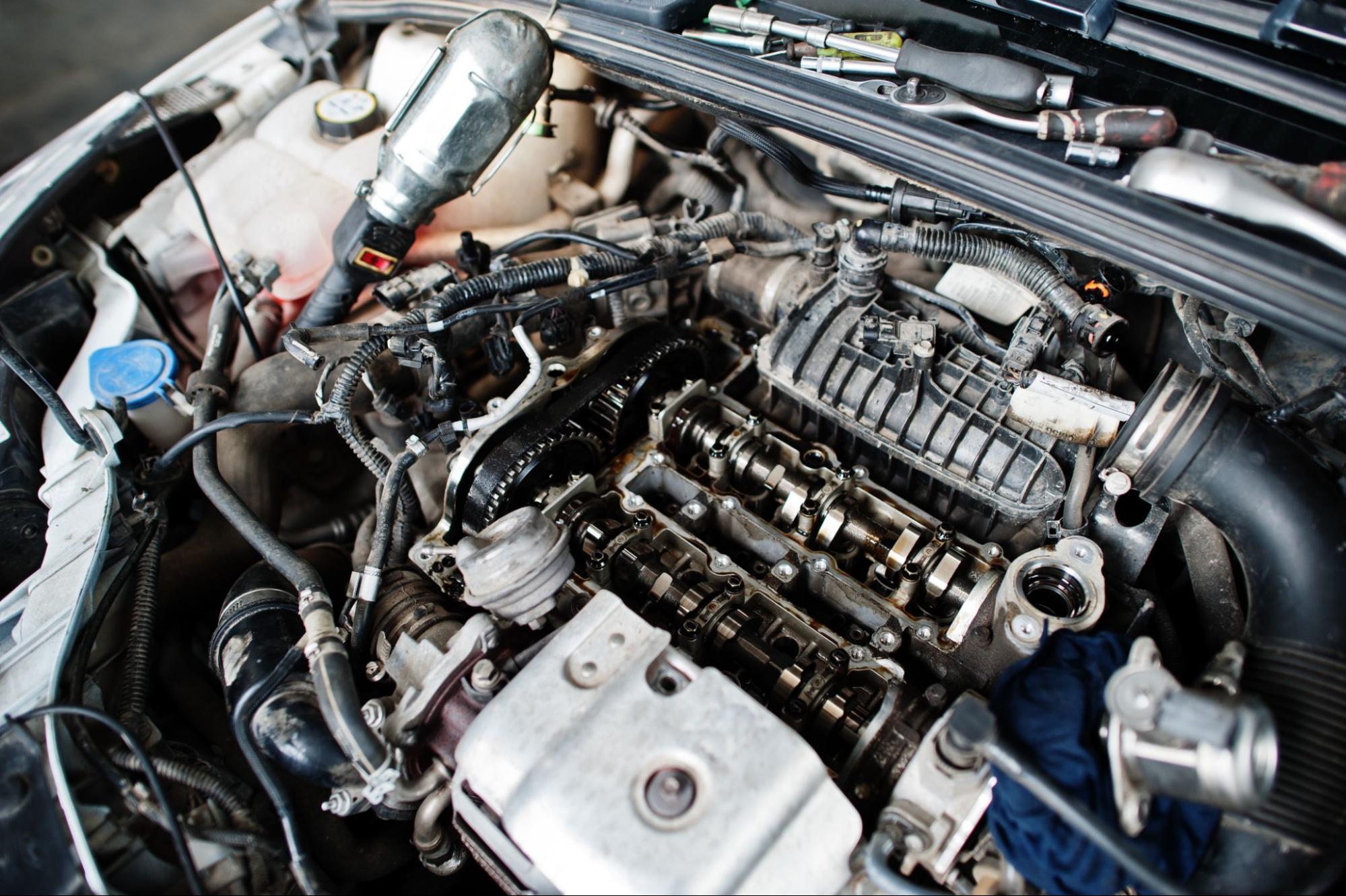

An engine rebuild involves disassembling the engine, inspecting every component, and replacing worn or damaged parts to restore it to working condition. The extent of the rebuild can vary, from a minor fix focusing on elements like gaskets and piston rings to a complete overhaul that replaces most internal components. You might need a rebuild if your vehicle shows signs like excessive smoke, engine knocking, or declining power, and addressing these issues early on can prevent total engine failure.

Factors That Affect the Cost of an Engine Rebuild

Several factors influence the cost of an engine rebuild, and understanding them helps you plan your budget effectively. The vehicle’s make and model, engine size, labor costs, and the type of rebuild needed all play significant roles. Parts and machine shop services also affect the final bill, and being aware of these factors can help you make informed financial decisions about whether to proceed with a rebuild.

Type of Vehicle and Engine Size

The vehicle you drive is primarily in rebuilding costs, as luxury and high-performance cars often require specialized parts and expertise. Additionally, engine size matters—a four-cylinder engine will generally cost less than a V6 or V8 because it’s simpler and requires fewer parts and labor hours. Larger or more complex engines, such as those in performance or off-road vehicles, often demand higher costs due to their intricate designs.

Type of Rebuild: Partial vs. Full

The extent of the partial or complete rebuild significantly impacts the cost. A partial rebuild, also known as a top-end rebuild, focuses on the cylinder head and upper engine components and tends to be quicker and less expensive. A complete rebuild replaces major parts like pistons, bearings, and the crankshaft, offering a comprehensive restoration but at a higher price. The severity of engine damage usually dictates which type of rebuild is necessary.

Labor Costs

Labor costs are often the most significant part of an engine rebuild, as skilled mechanics charge high hourly rates due to the complexity of the task. A typical rebuild can take anywhere from 15 to 25 hours, with regional variations in pricing—urban areas generally have higher labor rates than rural ones. The mechanic’s experience and the complexity of the engine can also influence the final labor cost.

Replacement Parts and Materials

The type of replacement parts you choose—whether OEM, refurbished, or aftermarket—can significantly affect the overall cost of the rebuild. OEM parts usually offer the best quality but are more expensive, while aftermarket or refurbished parts can be more affordable and have varying levels of reliability. Key components needing replacement include pistons, gaskets, bearings, and seals, all contributing to the final rebuild cost.

Machine Shop Services

Machine shop services often add substantial costs to an engine rebuild as they handle precision tasks like cylinder head resurfacing, engine block boring, and crankshaft balancing. These services are critical for ensuring your engine runs smoothly after the rebuild, but they can add several hundred to over a thousand dollars to the final bill. Skipping necessary machine work could result in poor engine performance or early failure.

Average Cost to Rebuild an Engine

The average cost to rebuild an engine typically ranges from $2,500 to $6,000, but the exact amount depends on the vehicle type, damage severity, and whether you choose professional or DIY services. Luxury cars, diesel engines, and performance vehicles can increase costs, while simpler engines in economy cars are more affordable. DIY rebuilds can save money but require time, skill, and proper tools, making them risky for inexperienced car owners.

Cost for a Four-Cylinder Engine Rebuild

Rebuilding a four-cylinder engine is usually the most affordable option, with costs ranging from $2,500 to $4,000. These engines are typically found in compact cars, sedans, and some small SUVs, and their simplicity means fewer parts and less labor. A rebuild can be a budget-friendly way to extend the life of your car without needing a complete replacement, especially if the vehicle is otherwise in good condition.

Cost for a V6 or V8 Engine Rebuild

Due to their larger size and additional complexity, rebuilding a V6 or V8 engine usually costs between $3,500 and $6,000. Trucks, full-size SUVs, and sports cars often feature these engines, which require more parts and labor. Performance V8 engines can be even more expensive due to specialized components, advanced tuning, and the need for highly skilled mechanics to handle the job.

Diesel Engine Rebuild Cost

Diesel engines are more expensive to rebuild than gasoline engines, typically ranging from $5,000 to $10,000, depending on the engine’s size and condition. Commonly found in trucks, commercial vehicles, and heavy machinery, diesel engines demand specialized knowledge and parts. Machine shop services can also increase the cost, making these rebuilds a significant investment for owners of diesel-powered vehicles.

Other Costs to Consider When You Rebuild an Engine

An engine rebuild can seem straightforward until unexpected expenses start piling up. While the upfront quote might cover labor and basic parts, there are often hidden costs that many car owners don’t anticipate. Overlooking these additional expenses can turn a manageable repair into a financial headache. Knowing these hidden costs will help you plan better and avoid surprises during the rebuild process:

Towing Fees

If your car isn’t drivable, towing it to a repair shop can be an unexpected expense. Depending on the distance and the type of vehicle, towing fees can range from $75 to over $200. If your car breaks down far from home, you should also cover additional mileage charges. Some insurance policies cover towing, but this cost can quickly add to your total bill without that protection.

Diagnostic Fees

Before a mechanic begins the rebuild, they’ll likely perform diagnostic tests to assess the full extent of the damage. These tests can cost anywhere from $100 to $250, depending on the complexity of the engine issue. In some cases, further inspections may uncover additional damage, leading to even higher costs. While some shops may waive this fee if you proceed with the rebuild, it’s a potential cost that should be considered.

Fluids, Filters, and Miscellaneous Parts

Rebuilding an engine often requires replacing more than just major components. Small but necessary parts like oil filters, air filters, spark plugs, and engine fluids can add unexpected costs. While each item might seem minor, they can easily add a few hundred dollars to the bill. Mechanics may not always include these extras in the initial quote, so clarifying what’s covered upfront is essential.

Shop Fees and Taxes

Many repair shops charge additional shop fees to cover the cost of materials used during repairs, such as rags, disposal fees, and basic supplies. These charges often range from five to ten percent of the total repair cost, which can significantly add to your final bill. On top of that, taxes on parts and labor can increase the price even further, especially in states with higher sales tax rates.

Rental Car or Transportation Costs

You may need alternative transportation if your engine rebuild takes several days or weeks. Depending on the vehicle and rental company, renting a car can cost anywhere from $30 to $70 per day. Even if you opt for public transportation, those costs can add up, especially if the rebuild takes longer than expected. Planning for transportation ahead of time can help reduce this financial strain.

Is Rebuilding an Engine Worthwhile?

Deciding whether to rebuild an engine depends on the vehicle’s value, overall condition, and your long-term plans for the car. Rebuilding can be cost-effective if the vehicle is otherwise in good shape, often saving money compared to replacing the engine or buying a new vehicle. However, if repair costs approach or exceed the car’s market value—or if other significant issues exist—it might be more practical to consider replacing the vehicle entirely.

Ways to Save Money on an Engine Rebuild

Making strategic choices can reduce the cost of an engine rebuild. Saving money doesn’t mean compromising quality—making informed decisions that balance cost and reliability can help stretch your budget while ensuring your vehicle gets the necessary repairs.

Shop Around for the Best Quote

Comparing quotes from different mechanics is a smart way to find the best deal on an engine rebuild. Request detailed cost breakdowns to understand precisely what each shop charges for parts, labor, and services. Negotiating prices and reading reviews can help you find reputable mechanics who offer quality service at fair rates, potentially saving you hundreds of dollars.

Use Refurbished or Aftermarket Parts

Opting for refurbished or aftermarket parts can significantly reduce rebuild costs without sacrificing quality. Refurbished parts are typically cleaned, repaired, and tested to ensure they function correctly, while aftermarket parts often come at a lower price than OEM options. However, it’s essential to research thoroughly to ensure that these parts meet your vehicle’s necessary performance and safety standards.

DIY Engine Rebuild If You Have the Skills

A DIY engine rebuild can save money if you have the necessary mechanical skills, tools, and time to complete the job correctly. While this route requires significant effort and expertise, it can reduce labor costs dramatically and provide a sense of accomplishment. However, mistakes made during a DIY rebuild can lead to costly repairs later on, making it a risky choice for inexperienced car owners.

Tackle Your Engine Rebuild Costs the Smart Way

Facing an engine rebuild isn’t just about fixing a car—it’s about investing wisely in something that keeps you moving forward. It’s not the breakdown that defines your journey but how you handle it. Knowing the costs, weighing your options, and making the right call can save you thousands and extend the life of your vehicle. Don’t let engine trouble hold you back—take charge, ask the right questions, and get the best value for your money. Your car still has miles left; it just needs you to make the first move.

Don’t let engine trouble slow you down—explore the Dark Night Specialties blog for expert advice and cost-saving tips.