Creating a professionally built car isn’t just about assembling parts; it’s an intricate dance of creativity, engineering, and precision. For many, crafting a vehicle from scratch carries an irresistible appeal—turning imagination into a machine that commands the road. Every detail reflects expertise and passion, from the roar of a custom engine to the gleam of a flawless paint job. Understanding how professionals bring these masterpieces to life reveals the dedication and craftsmanship behind every curve, bolt, and stitch.

What Does Professionally Building a Car Mean?

Building a car goes far beyond standard assembly-line production. It involves a tailored, detailed process where each component is carefully selected, crafted, and fitted to meet specific goals. Whether it’s a luxury custom build, a high-performance sports car, or a fully restored classic, professionals prioritize quality, innovation, and precision. Every detail, from the engine specs to the interior stitching, is crafted with intention and skill. This level of detail distinguishes a professional build from factory-manufactured vehicles.

Custom Builds vs. Factory Production

Factory-built cars are for the masses, prioritizing efficiency and affordability. In contrast, custom builds offer unique designs and specialized features tailored to the owner’s preferences. Factory cars follow a set design, while professional builds allow for innovation and personalization. This freedom often results in superior performance, style, and individuality. Car enthusiasts usually seek custom builds for that unique touch they can’t get from a showroom model.

The Process of Building a Car Professionally

The journey of professionally building a car is a meticulous blend of design, engineering, and craftsmanship. Every phase, from concept to completion, demands expert knowledge, attention to detail, and seamless collaboration. This structured process unfolds in distinct stages, each playing a crucial role in shaping the final product. Below are the essential steps that define the professional car-building process:

1. The Planning Phase

Every great build begins with a solid plan. Professional car builders don’t just dive in—they strategize every detail from the start. This phase involves shaping the overall vision, deciding on specifications, and understanding client needs. Budgeting, timelines, and design goals must all be established before the first part is even touched. A well-structured plan sets the foundation for every step that follows.

Laying Out a Clear Design Concept

A strong design concept shapes the entire building process. It defines the car’s purpose for racing, luxury, or everyday use. Builders work with clients or personal visions to map the style, performance goals, and unique features. Design sketches and mood boards often come into play at this stage. These visuals guide the team in crafting a car that aligns with the intended vision.

Custom Designing

Professional builders often choose between creating something new or modifying an existing framework. Custom designs involve building from scratch, allowing complete creative freedom. Modifications, on the other hand, enhance existing models, improving performance or aesthetics. Both paths require a detailed understanding of engineering and design principles. The choice depends on the desired outcome and available resources.

Budgeting and Timeline Considerations

Budgeting is crucial in professional car building since costs can quickly escalate. Builders factor in materials, labor, and unexpected expenses. Timeframes are equally important, with clear milestones set for each build phase. Delays can lead to increased costs, so staying on schedule is essential. A realistic budget and timeline help ensure the project remains manageable and efficient.

2. Design and Engineering

Design and engineering shape the core of any professional car build. Every feature is meticulously planned, from the body structure to the powertrain. Professionals rely on a blend of artistic vision and technical precision to bring the design to life. Aerodynamics, performance, and safety all play critical roles during this phase. A strong foundation ensures the car will function as beautifully as it looks.

Creating Technical Drawings and 3D Models

Before physical work begins, technical drawings help visualize the car’s structure and mechanics. These drawings provide exact measurements, materials, and specifications. Engineers often use advanced 3D modeling software to create detailed digital blueprints. It allows the team to identify potential design flaws early in the process. These models are essential for ensuring that every element fits together perfectly.

Aerodynamics and Structural Integrity

A car’s aerodynamics and structural strength heavily influence its performance. Aerodynamic designs reduce air resistance, increasing speed and fuel efficiency. Structural integrity ensures the vehicle can handle driving, turning, and braking stress. Engineers test models through simulations to fine-tune these elements. A well-balanced car offers both speed and safety.

Collaborating Between Designers and Engineers

Designers and engineers work hand-in-hand throughout the building process. While designers focus on aesthetics and user experience, engineers handle technical functionality. Their collaboration ensures that the final product is visually stunning and mechanically sound. Regular meetings and design reviews help keep everyone aligned. This teamwork results in a well-rounded, high-performing vehicle.

3. Selecting the Right Materials

Material selection directly impacts performance, durability, and aesthetics. Professional builders choose materials that meet specific needs—lightweight metals for speed or durable composites for longevity. Each part of the car demands a different material choice based on its role. The right combination of materials can enhance speed, strength, and safety.

Metals, Composites, and Advanced Materials

Traditional materials like steel and aluminum remain popular in car building. Steel offers strength, while aluminum provides a lightweight alternative. Advanced composites, like carbon fiber, are prized for their balance of strength and lightness. Professionals often use a mix of materials to optimize performance. The goal is to balance durability, weight, and cost.

Factors Influencing Material Choice

Several factors influence material selection, including weight, strength, and cost. A racing car might prioritize lightweight materials to boost speed. Luxury builds often emphasize aesthetics, using high-end finishes like leather or exotic wood. Environmental impact is also a growing consideration, with builders exploring sustainable options. Every choice must support the car’s intended purpose.

How Materials Affect Performance and Safety

Materials significantly affect a car’s handling, speed, and safety. Lightweight materials improve acceleration and fuel efficiency. Durable metals enhance safety by providing structural support during collisions. Even the tires’ composition affects performance, impacting grip and handling. Each material choice contributes to the vehicle’s overall reliability and functionality.

4. Fabrication and Assembly Process

The fabrication and assembly process transforms a car from concept to reality. Technical skills and craftsmanship take center stage. Each chassis, body, engine, and wiring component is carefully constructed and installed. Every bolt and weld must meet exacting standards. The goal is to create a cohesive, fully functioning machine.

Constructing the Chassis and Body

The chassis forms the car’s structural backbone. It must be strong enough to support the vehicle’s weight while maintaining flexibility for smooth driving. Builders often use welded steel frames or lightweight aluminum alloys. Once the chassis is complete, the body is attached, shaped, and refined. Attention to detail at this stage ensures proper alignment and structural integrity.

Installing the Powertrain Components

The powertrain includes the engine, transmission, and drivetrain—key components determining the car’s performance. Installing these systems requires technical precision and expertise. Each part must fit seamlessly within the design for optimal functionality. Builders also consider how these components will affect weight distribution. Proper installation is crucial for achieving peak performance.

Electrical System and Wiring Setup

Modern cars rely on complex electrical systems for everything from lighting to navigation. Professional builders carefully install wiring to ensure safety and reliability. It involves connecting sensors, power supplies, and onboard electronics. A poorly wired system can lead to malfunctions or safety hazards. Precision and testing are critical during this phase.

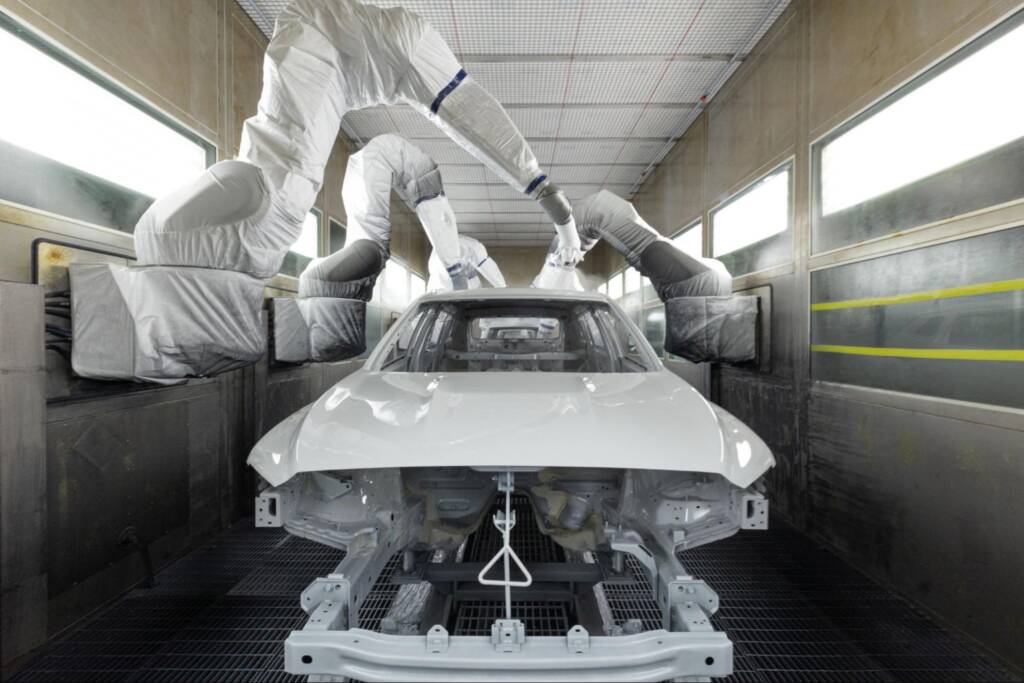

5. Painting and Finishing Touches

The final appearance of a professionally built car often reflects the builder’s attention to detail. A flawless paint job enhances both beauty and protection. The finishing touches—decals, badges, and custom elements—bring the car’s personality to life. Every layer of paint and polish contributes to the overall impression of craftsmanship and style.

Prepping the Surface for Painting

Before painting, the car’s body must be carefully prepped. Builders sand and clean the surface to ensure smoothness. Any imperfections are corrected with filler or sanding. This preparation helps the paint adhere properly and achieve a polished finish. A clean surface also prevents defects like bubbles or uneven textures.

Applying Primer, Base Coat, and Clear Coat

The painting process involves several layers, starting with a primer. The primer helps the base coat stick and offers corrosion protection. The base coat adds color and depth, creating the car’s visual appeal. Finally, a clear coat provides shine and protection against environmental damage. Each layer is applied with precision for a high-quality finish.

Adding Aesthetic Details and Custom Features

Beyond paint, custom features like decals, badges, and trims add personality to the vehicle. These details often reflect the owner’s style or brand identity. Builders carefully position and secure these elements for maximum visual impact. Custom finishes, such as matte or metallic paints, can enhance the car’s unique appeal.

6. Interior Customization and Detailing

A car’s interior is just as important as its exterior. Professional builders focus on comfort, functionality, and aesthetics inside the vehicle. From luxurious leather seats to state-of-the-art sound systems, the interior reflects craftsmanship and innovation. Every detail is designed for comfort, convenience, and style.

Designing the Interior Layout

The interior layout must be both functional and visually appealing. Builders consider seating arrangement, dashboard placement, and ergonomic factors. Space optimization ensures the car remains comfortable for drivers and passengers. Luxury builds often feature custom seating configurations and unique design elements, creating a personalized and inviting space.

Installing Seats, Dashboards, and Electronics

Seats and dashboards are carefully installed to align with the overall design. Builders integrate modern technology, such as touchscreen systems and advanced controls. Attention to detail ensures that every component fits seamlessly. Safety features, like airbags and seat belts, are also carefully installed. The goal is to create a high-functioning, visually appealing interior.

Adding Upholstery, Sound Systems, and Lighting

Custom upholstery can transform a car’s interior into a luxurious space. High-quality materials, such as leather or suede, enhance comfort and style. Builders also install premium sound systems for an immersive driving experience. Custom lighting adds ambiance, highlighting key design elements. These finishing touches elevate the overall driving experience.

7. Mechanical Testing and Performance Tuning

No car is complete without rigorous testing and fine-tuning. Professional builders conduct detailed inspections to ensure every system functions flawlessly. Performance tuning adjusts the car’s mechanics for optimal speed, handling, and efficiency. This phase guarantees that the finished vehicle delivers on both quality and performance.

Inspecting Engine and Mechanical Systems

Every mechanical system undergoes a thorough inspection before the car hits the road. Builders check for issues like leaks, faulty wiring, or loose fittings. The engine is tested for power output and efficiency. Ensuring mechanical reliability is essential for safety and performance. Any issues are addressed immediately to avoid future problems.

Conducting Safety Tests and Road Simulations

Safety tests simulate real-world driving conditions to assess the car’s durability and responsiveness. Braking tests, crash simulations, and stress tests identify potential weaknesses. These tests ensure that the car meets all safety regulations. Only after passing rigorous inspections can the vehicle be deemed road-ready.

Fine-Tuning for Optimal Performance

Performance tuning adjusts elements like suspension, engine output, and transmission response. Builders analyze test data to optimize driving dynamics. The goal is to improve acceleration, handling, and fuel efficiency. Every adjustment enhances the overall driving experience, ensuring the car performs at its best.

Bring Your Vision to Life by Building a Car Professionally

A professionally built car is more than a machine—it’s a statement of creativity, craftsmanship, and individuality. It reflects ambition, skill, and the relentless pursuit of perfection. If creating something entirely your sparks even a flicker of excitement, now is the time to turn that spark into motion. The road from concept to creation might be challenging, but every twist and turn is worth it for the reward at the finish line. Don’t just admire the art of car building—become part of it. Start shaping your vision today, and let the journey toward your custom masterpiece begin.

Fuel your passion for cars—explore more expert insights on the Dark Night Specialties blog.