Something precise happens under the hood every time you press the gas pedal. Fuel doesn’t just flow; it’s measured, timed, and delivered with incredible accuracy. That’s how fuel injection works; it’s quietly running the show in modern engines. Most drivers use it every day without ever considering how it functions. Still, knowing how it affects power, efficiency, and reliability gives you a real edge.

What is Fuel Injection and What Does it Do?

Fuel injection is a system that delivers fuel directly into an engine’s combustion chamber or intake port. It utilizes sensors and electronic controls to inject precise amounts of fuel based on the engine’s conditions. It helps the engine run efficiently, burn fuel cleanly, and respond faster to acceleration. It replaces older methods, such as carburetors, offering more accurate fuel delivery and improved performance.

A Precise Fuel Delivery Method

Unlike older systems, fuel injection doesn’t rely on air pressure to pull fuel in. Instead, it uses precise electronic controls to spray the right fuel. This process helps the engine burn fuel more efficiently. The fuel injector valve opens and closes at exact intervals, allowing a fine mist into the chamber. That mist mixes with air for a balanced and powerful ignition.

How it Differs from Carburetion

Carburetors once dominated before fuel injection took over. They mix air and fuel before sending it to the engine. But they often struggle with precision and environmental demands. Fuel injection solves those issues by delivering more controlled results. It uses sensors and computers to adjust fuel based on engine speed, temperature, and load. That adaptability makes it more reliable and efficient in all conditions.

Why it Replaced Older Systems

Stricter emission rules changed everything. Carburetors couldn’t meet modern standards without heavy modification. Fuel injection became the default because it offered a cleaner burn. It also helped automakers improve both power and economy simultaneously. Additionally, it adapted better to electronic engine controls and diagnostic tools.

How Fuel Injection Works

Understanding fuel injection starts with breaking down its working parts. Each component plays a role in precision and performance. Together, they create a fine-tuned process that balances power and efficiency. Knowing how it works helps drivers identify problems early and drive more effectively.

The Core Components

At the heart of the system are injectors, fuel pumps, pressure regulators, and control modules. The fuel pump moves gas from the tank to the engine. A regulator maintains stable pressure, allowing the system to respond quickly. Injectors then spray fuel based on timing signals from the engine control unit (ECU). Sensors track air intake, engine load, and temperature, instantly adjusting the output.

Types of Fuel Injection Systems

Not all fuel injection systems are alike. Throttle body injection is the simplest, involving the placement of one or two injectors in the throttle body. Multi-point injection provides each cylinder with its own injector, offering improved precision. Direct injection sends fuel straight into the combustion chamber for maximum control. Sequential injection times each spray with the piston’s movement. Each type suits different engine designs and performance goals.

The Fuel Delivery Process Step-By-Step

The process begins when you turn the key. The fuel pump activates, sending gas through filters to the injectors. The ECU receives sensor data, then signals each injector when and how much to spray. That spray combines with air, compresses, and ignites for combustion. Afterward, exhaust sensors provide feedback to fine-tune the next cycle. This constant loop keeps your engine running smoothly and efficiently.

Benefits of Fuel Injection

Drivers may not see the system in action but feel its impact. Fuel injection makes engines quicker to respond, cheaper to run, and cleaner overall. It’s more than just a mechanical upgrade; it’s a more innovative way to use fuel. From smoother startups to reduced waste, the advantages keep adding up.

Improved Fuel Efficiency

Fuel injection systems use data to match fuel delivery to demand. That precision reduces waste during acceleration, cruising, or idling. As a result, engines burn less fuel without losing power. Over time, that adds up to real savings at the pump. Especially for high-mileage drivers, the impact is hard to ignore.

Cleaner Emissions and Environmental Impact

Every spray from an injector is controlled to reduce unburned fuel. That means fewer pollutants leave the tailpipe. Engines with fuel injection typically meet tighter emissions limits with ease. This cleaner combustion helps reduce smog and greenhouse gases. For drivers in urban or regulated areas, it’s not just helpful; it’s necessary.

Enhanced Engine Performance

Fuel injection creates faster throttle response. That’s because it adjusts fuel delivery in milliseconds. Drivers notice smoother acceleration, better torque, and fewer engine hiccups. It also handles changes in altitude or temperature without manual tuning. Performance cars and work trucks alike benefit from that extra consistency.

Common Fuel Injection Problems

Even the most reliable systems need care. Fuel injection issues can creep in over time, often starting small. Knowing the common signs and causes helps prevent bigger damage. Some problems are easy to fix, while others require expert assistance.

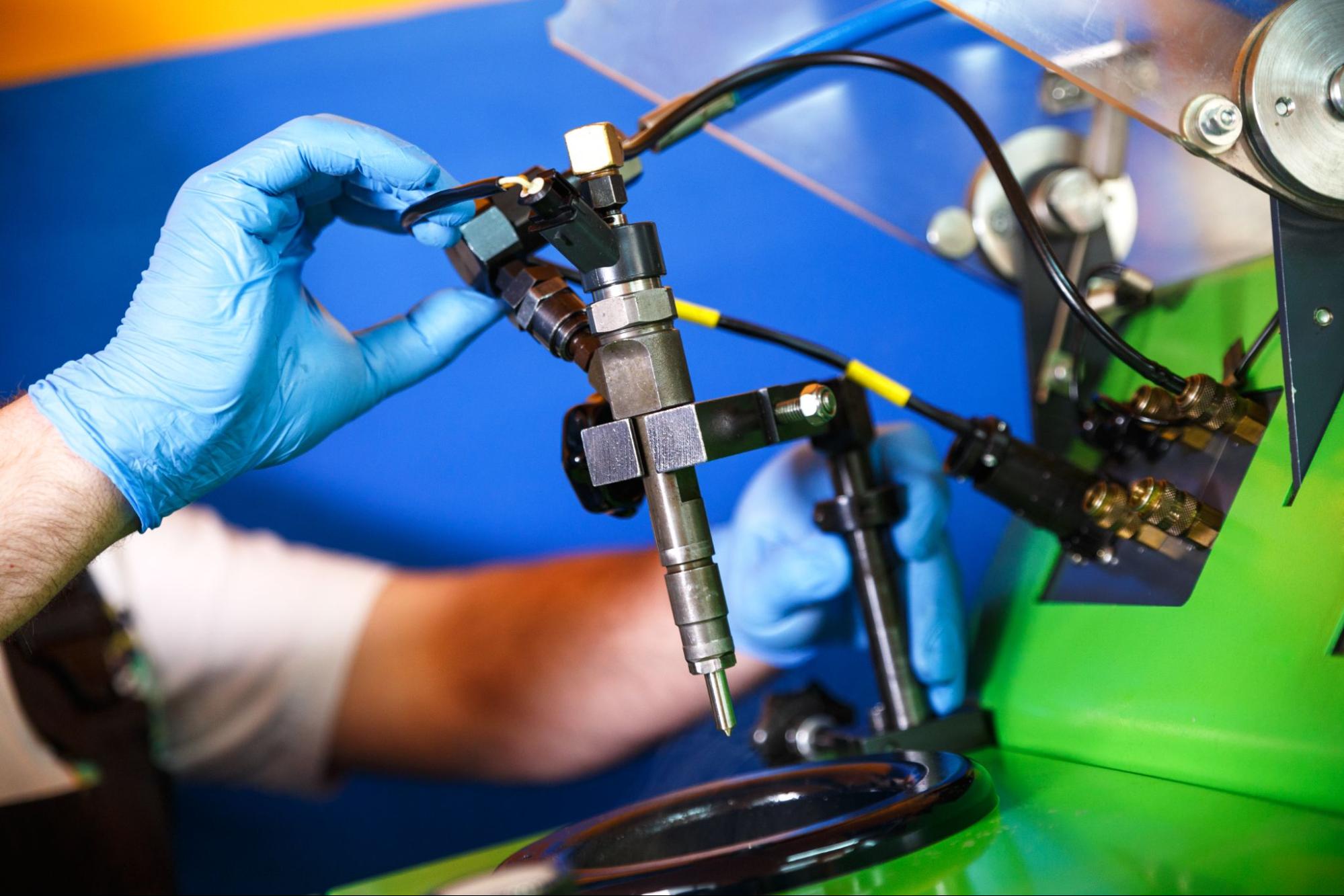

Clogged or Dirty Injectors

Injectors spray fuel in a fine mist. When they become clogged, the mist becomes uneven or weak. You might feel misfires, rough idling, or slow acceleration. Buildup usually comes from low-quality fuel or skipped maintenance. Cleaning additives or professional servicing can quickly restore performance.

Electronic Failures or Sensor Issues

The ECU and sensors make the system smart. When one fails, fuel delivery becomes inaccurate. A faulty sensor may send insufficient data, resulting in either too much or too little fuel. That leads to poor mileage and potential engine strain. Diagnosing these issues typically requires the use of a scan tool or the assistance of a technician.

Symptoms of a Malfunctioning System

Hard starts, poor throttle response, or black exhaust smoke are signs of trouble. Sometimes, you may notice a sudden drop in your fuel economy. If the ECU detects an issue, the check engine light may flash. Delaying repairs can damage spark plugs, O2 sensors, or catalytic converters. It’s better to act when symptoms first appear than risk deeper engine issues.

Maintenance Tips for Fuel Injection Systems

Good habits keep your fuel injection running like new. It doesn’t require constant attention, but it does need proper care. Regular upkeep protects your engine and wallet in the long run. Here’s how to keep things in top shape.

Cleaning Intervals and Tools to Use

Use fuel injector cleaners every 3,000 to 5,000 miles. These additives break down deposits before they cause clogs. For deeper cleans, a mechanic can flush the system professionally. Some kits let you clean injectors without removing them. If you drive in dusty or stop-and-go areas, clean more often.

Choosing the Right Fuel and Additives

High-quality fuel burns cleaner and leaves fewer deposits. Cheap gas might save you a few bucks now, but it ultimately costs more. Some fuels include detergents that help clean the system as you drive. Additives can boost performance, but choose ones approved for your engine. Always read the label to avoid damage.

Professional vs. DIY Servicing

You can handle light maintenance at home. Additives and occasional filter changes are easy and effective. However, for more in-depth diagnostics or injector replacement, visit a certified performance specialty shop. Mechanics have tools to test pressure, spray patterns, and timing. Investing in professional checks helps spot problems early and extend your engine’s life.

How Fuel Injection is Shaping the Future of Driving

Fuel injection is no longer just about combustion; it’s evolving fast. New technology and regulations are pushing it into smarter territory. As powertrains evolve, fuel systems must adapt or risk falling behind. The next generation of vehicles relies on precision more than ever.

Integration With Electric and Hybrid Vehicles

Even hybrid cars still use combustion engines. Fuel injection adapts to their unique demands. It must balance electric assistance with fuel savings in real-time. Engineers now design systems that shut off or adjust injection instantly. That flexibility is key in modern hybrid design.

Advances in Precision and Technology

Modern injectors can handle higher pressures and tighter tolerances. Direct injection systems now spray fuel multiple times within a single cycle. Combined with turbocharging, this allows more power from smaller engines. Machine learning also enters the scene, improving response over time. These innovative systems will soon become the standard, not an option.

Impact on Fuel Economy Regulations

Governments continue to tighten fuel and emissions targets. Fuel injection helps meet those limits without sacrificing performance. Automakers rely on advanced injection to pass tests and lower fleet averages. The future will include stricter benchmarks, and fuel systems must evolve accordingly. Staying ahead means designing with injection as a core feature, not an afterthought.

Know What Fuel Injection Means for Your Vehicle

Fuel injection isn’t just an engine feature; it’s a deciding factor in performance, longevity, and cost. Overlooking it means ignoring what keeps your vehicle running at its best. When problems start small, fixing them early can prevent thousands in repairs. Routine care beats emergency fixes every time. If your vehicle still uses outdated systems or hasn’t had a fuel check, now’s the time to act with clarity and purpose.

Want to learn more about performance upgrades? Visit the Dark Night Specialties blog for expert insights and real-world solutions.